Product Details

BS series(Bobbin/Segment Core, Thin/Median Wire, High Speed)

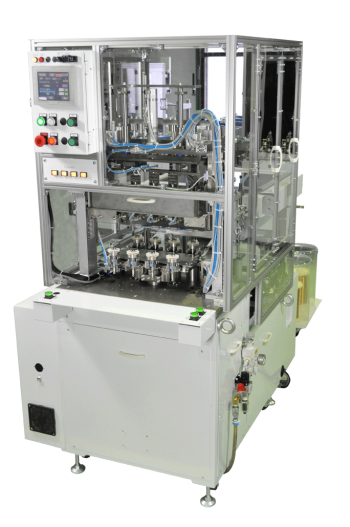

BS-520/540/560/580

CNC Vertical Spindle Winding Machine

BS-520/540/560/580

CNC Vertical Spindle Winding Machine

Basic Feature

- Original method of setting target item, not horizontally but vertically, will achieve high speed and stable perfect winding.

- Variety of spindle pitch and number of spindles are available to fit the bobbin size and production volume.

Common Feature

- High-performance AC servo motor for all drive axes, dedicated winding controls for Bestec are installed.

- Wire routes are set to the height of workers view for better working property.

- Turn table system as standard equipment. Bobbins could be changed during winding.

- Twist unit, coat peeling unit, terminal calking unit could be added as option.

- Automation lines are available with other process. Please contact for any interest.

MACHINE SPECIFICATIONS

| MODEL | BS-520 | BS-540 | BS-560 | BS-580 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WOUNDABLE ITEM | BOBBIN / SEGMENT CORE | |||||||||

| NUMBER OF WINDING HEAD | 1 | 2 | 2 | 4 | 6 | 8 | 6 | 4 | 8 | 12 |

| DRIVE AXES | 4-AXES | |||||||||

| CONTROL | AC SERVO FOR ALL AXES | |||||||||

| SPINDLE PITCH (MM) | - | 80 | 160 | 80 | 52 | 40 | 80 | 132 | 80 | 52 |

| WINDING SPEED | MAX 15000 (DEPENDING ON ITEM) | |||||||||

| WOUNDABLE WIRE SIZE | MAX φ0.5mm (THICK WIRE VERSION: MAXφ1.0) | |||||||||

| WIRE CUT | NIP & CUTTER / AIR NIPPER | |||||||||

| TENSION DEVICE | MANUALLY ADJUSTABLE MAGNET BRAKE (NC ADJUSTABLE: OPTION) | |||||||||

| MAIN POWER SUPPLY | AC 3-PHASE 200V 2KVA | |||||||||

| PNEUMATIC SUPPLY (MPA) | 0.4 – 0.6 | |||||||||

| MACHINE SIZE (mm) ※ WITHOUT TENSION DEVICE | 750W x 2200L x 1900H | 900W x 2200L x 1900H | 1200W X 2200L X 1900H | 1300W x 2200L x 1900H | ||||||

| MACHINE WEIGHT (KG) | 550 | 650 | 1400 | 900 | ||||||

| LOAD / UNLOAD | MANUAL (TURN TABLE SYSTEM AVAILABLE) | |||||||||

| SAFETY GUARD | FRONT AREA SENSOR/SAFTY COVER ETC… | |||||||||

| OPERATION | ON TOUCH PANEL | |||||||||